Process Deep Dive: How the Lacha paratha Making Machine Fully Automatic Company Advances Layered Flatbread Production

SHANGHAI, SHANGHAI, CHINA, February 3, 2026 /EINPresswire.com/ -- As global demand for layered flatbreads such as Lacha Paratha and Roti Canai continues to rise, manufacturers are increasingly seeking production methods that balance traditional texture with industrial consistency. Within this context, the concept of a Lacha paratha Making Machine Fully Automatic Company has emerged as a key development in the automation of laminated flatbread production.

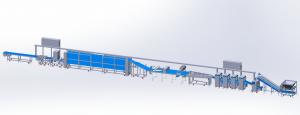

CHENPIN FOOD MACHINE CO., LTD. has recently highlighted its fully automatic Lacha Paratha Production Line Machine as part of its ongoing efforts to standardize complex flatbread processes while maintaining structural integrity and product uniformity at scale.

Translating Traditional Techniques into Automated Processes

Lacha Paratha is traditionally produced through repeated manual steps, including stretching, oiling, rolling, and resting the dough to form distinct layers. These steps rely heavily on operator skill, making large-scale consistency difficult to achieve.

To address this challenge, CHENPIN has engineered a production line that converts each traditional operation into a discrete, mechanically controlled stage. Rather than compressing multiple actions into a single step, the system applies lamination progressively through a structured sequence:

Dough chunking → Continuous sheeting → Sheet stretching → Automatic oil brushing → Sheet dividing → Automatic rolling → Relaxing and conveying → Cutting → Rolling and forming → Pressing and filming → Quick freezing → Packaging

This segmented workflow is designed to reduce mechanical stress on the dough while preserving gluten structure throughout the process. Balanced sheeting tension, uniform oil application, and programmed relaxing intervals allow the dough to stabilize before further shaping, supporting consistent layer definition.

Production Capacity and Configuration Options

The Lacha Paratha Production Line Machine is available in multiple configurations to accommodate varying production requirements. The CPE-3368 model supports output levels of approximately 7,500 to 10,000 pieces per hour, while the CPE-3268 model is designed for capacities ranging from 5,000 to 7,000 pieces per hour.

Both systems allow adjustments to dough weight, product diameter, and layer structure based on specific formulation needs. The production line can also be integrated with CHENPIN’s CP-788 series pressing and filming machines, enabling continuous processing from forming to film application with minimal manual intervention.

Dough Conditioning and Layer Formation Control

A key factor in layered flatbread production is dough conditioning prior to lamination. The system incorporates multi-stage relaxing conveyors that allow internal dough stress to dissipate gradually. In high-capacity configurations, relaxing sections can extend up to six meters and include multiple relaxing layers to support stable processing at increased speeds.

Layer formation is achieved through synchronized rolling and folding modules that replicate traditional hand techniques using controlled stretching ratios. This approach avoids excessive compression, allowing oil-separated layers to form naturally and consistently across production runs.

Automation and System Coordination

The production line operates under centralized control systems that coordinate conveying speed, roller pressure, and processing timing across each stage. Operators can monitor and adjust parameters through a unified interface, supporting consistent operation and reduced labor dependency.

Optional modules, including ingredient sprinkling systems, can be incorporated to support additional product variations. This modular design allows manufacturers to adapt production lines to different regional formulations without altering core equipment architecture.

Industry Implications

CHENPIN’s development reflects a broader industry trend toward process-oriented automation, in which equipment is designed around the physical behavior of dough rather than isolated mechanical functions. By aligning stretching, oiling, rolling, and relaxing into a synchronized system, the production line supports repeatability and stability during extended production cycles.

This approach enables manufacturers to scale layered flatbread production while maintaining defined layers, uniform thickness, and consistent texture.

Conclusion

As demand for laminated flatbreads continues to expand globally, production systems capable of combining automation with process control are becoming increasingly relevant. The Lacha Paratha Production Line Machine developed by CHENPIN illustrates how structured automation can be applied to traditionally manual processes, supporting industrial output without compromising fundamental product characteristics.

For more information about CHENPIN’s Lacha Paratha Production Line Machine and automated flatbread solutions, please visit: https://www.chenpinmachine.com/.

CHENPIN FOOD MACHINE CO., LTD. has recently highlighted its fully automatic Lacha Paratha Production Line Machine as part of its ongoing efforts to standardize complex flatbread processes while maintaining structural integrity and product uniformity at scale.

Translating Traditional Techniques into Automated Processes

Lacha Paratha is traditionally produced through repeated manual steps, including stretching, oiling, rolling, and resting the dough to form distinct layers. These steps rely heavily on operator skill, making large-scale consistency difficult to achieve.

To address this challenge, CHENPIN has engineered a production line that converts each traditional operation into a discrete, mechanically controlled stage. Rather than compressing multiple actions into a single step, the system applies lamination progressively through a structured sequence:

Dough chunking → Continuous sheeting → Sheet stretching → Automatic oil brushing → Sheet dividing → Automatic rolling → Relaxing and conveying → Cutting → Rolling and forming → Pressing and filming → Quick freezing → Packaging

This segmented workflow is designed to reduce mechanical stress on the dough while preserving gluten structure throughout the process. Balanced sheeting tension, uniform oil application, and programmed relaxing intervals allow the dough to stabilize before further shaping, supporting consistent layer definition.

Production Capacity and Configuration Options

The Lacha Paratha Production Line Machine is available in multiple configurations to accommodate varying production requirements. The CPE-3368 model supports output levels of approximately 7,500 to 10,000 pieces per hour, while the CPE-3268 model is designed for capacities ranging from 5,000 to 7,000 pieces per hour.

Both systems allow adjustments to dough weight, product diameter, and layer structure based on specific formulation needs. The production line can also be integrated with CHENPIN’s CP-788 series pressing and filming machines, enabling continuous processing from forming to film application with minimal manual intervention.

Dough Conditioning and Layer Formation Control

A key factor in layered flatbread production is dough conditioning prior to lamination. The system incorporates multi-stage relaxing conveyors that allow internal dough stress to dissipate gradually. In high-capacity configurations, relaxing sections can extend up to six meters and include multiple relaxing layers to support stable processing at increased speeds.

Layer formation is achieved through synchronized rolling and folding modules that replicate traditional hand techniques using controlled stretching ratios. This approach avoids excessive compression, allowing oil-separated layers to form naturally and consistently across production runs.

Automation and System Coordination

The production line operates under centralized control systems that coordinate conveying speed, roller pressure, and processing timing across each stage. Operators can monitor and adjust parameters through a unified interface, supporting consistent operation and reduced labor dependency.

Optional modules, including ingredient sprinkling systems, can be incorporated to support additional product variations. This modular design allows manufacturers to adapt production lines to different regional formulations without altering core equipment architecture.

Industry Implications

CHENPIN’s development reflects a broader industry trend toward process-oriented automation, in which equipment is designed around the physical behavior of dough rather than isolated mechanical functions. By aligning stretching, oiling, rolling, and relaxing into a synchronized system, the production line supports repeatability and stability during extended production cycles.

This approach enables manufacturers to scale layered flatbread production while maintaining defined layers, uniform thickness, and consistent texture.

Conclusion

As demand for laminated flatbreads continues to expand globally, production systems capable of combining automation with process control are becoming increasingly relevant. The Lacha Paratha Production Line Machine developed by CHENPIN illustrates how structured automation can be applied to traditionally manual processes, supporting industrial output without compromising fundamental product characteristics.

For more information about CHENPIN’s Lacha Paratha Production Line Machine and automated flatbread solutions, please visit: https://www.chenpinmachine.com/.

CHENPIN FOOD MACHINE CO., LTD

CHENPIN FOOD MACHINE CO., LTD

+86 2157674551

sales@chenpinsh.com

Visit us on social media:

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.