Affordable UVeye Alternative for Car Body Damage Scanner: Exploring Elscope Vision Cost-Efficient Solutions

SHANGHAI, CHINA, January 28, 2026 /EINPresswire.com/ -- The transition from manual inspection to digital transparency has fundamentally altered the automotive landscape. Not long ago, a vehicle appraiser would circle a car with a clipboard, relying on the naked eye and a flashlight to spot hairline scratches or structural irregularities. Today, that process is being replaced by high-speed imaging and artificial intelligence.

While pioneers like UVeye have successfully validated the market for automated vehicle scanning solutions, a new challenge has emerged: scalability for the broader market. As global dealerships and logistics hubs seek to digitize without prohibitive capital expenditure, the demand for an Affordable UVeye Alternative for Car Body Damage Scanner has reached a tipping point.

A car body damage scanner is no longer just a luxury for high-end OEMs; it is a critical tool for transparency. These systems utilize high-resolution camera arrays and AI algorithms to identify dents, scratches, and hail damage within seconds as a vehicle drives through a scanning arch. From rental car returns where disputes over "pre-existing damage" are common, to massive automotive auction houses requiring standardized condition reports, these vehicle inspection systems provide a "digital twin" of a car’s exterior, ensuring that no defect goes undocumented.

The Democratization of AI: From Premium Luxury to Industry Standard

The automotive industry is currently navigating a period of intense digital transformation. For years, AI-powered automated vehicle scanning solutions were viewed as a premium "add-on" reserved for the most profitable flagship dealerships or high-volume manufacturers. However, the industry is witnessing a significant shift. The market now understands that AI is not just about the "wow factor"; it is about precision, liability protection, and operational speed.

The primary friction point remains the Return on Investment (ROI). While the value of high-speed scanning is undisputed, many mid-sized dealerships, independent repair shops, and regional fleet operators find the initial investment for tier-one systems difficult to justify. This has paved the way for Elscope Vision, powered by New Tech Automotive Technology (Shanghai) Co., Ltd. (NTA), to bridge the "digital divide." By focusing on cost-efficiency and modular engineering, they provide a path for businesses to adopt elite-level inspection systems for vehicles without the traditional financial barriers.

Elscope Vision: Engineering Full-Stack Solutions for Global Markets

Founded in 2014, NTA has spent a decade perfecting the intersection of hardware and AI. Unlike many companies that simply assemble third-party components, Elscope Vision maintains a full-stack R&D approach. This means the hardware engineering, automation logic, AI algorithms, and cloud architecture are all developed in-house. This vertical integration is the key to their competitive pricing and technical reliability.

Their flagship offerings provide a comprehensive 4-in-1 vehicle inspection system that addresses every critical touchpoint of a vehicle’s exterior:

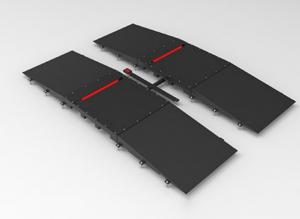

Arch Scanner (Body & Hail): This car body damage scanner is specifically engineered for high-fidelity detection. While general scanners often struggle with subtle textures, the Dragate system excels in identifying hail damage and PDR (Paintless Dent Repair) requirements. This specialization makes it a preferred choice for insurance adjusters and specialized repair centers.

Undercarriage Scanner (Undercarriage): The undercarriage scanner utilizes 4K high-definition imaging to detect fluid leaks, structural rust, or component wear that is often missed during a quick manual lift inspection.

Tire Tread Depth Scanner & Tire Sidewall Scanner (Tires):Precision is critical to tire safety. The integrated tire tread depth scanner and tire sidewall scanner these two scanners combine line-laser imaging technology with high-resolution visual capture to deliver accurate, repeatable tread depth measurements across all grooves. In parallel, the tire sidewall scanner uses photographic imaging to record key tire information—including tire size, brand, and manufacturing date—while AI algorithms automatically identify sidewall defects such as bulges, cracks, and abnormal deformations. Together, the system provides comprehensive, data-driven tire condition documentation to support consistent and reliable safety assessments.

The Value Proposition: High Performance at a Controlled TCO

When evaluating an affordable Uveye alternative for car body damage scanner, the Total Cost of Ownership (TCO) extends beyond the purchase price. Elscope Vision has optimized the "soft costs" of deployment. Their systems feature modular designs and flexible installation modes—whether surface-mounted, flush-mounted, or mobile configurations. This flexibility significantly reduces site preparation and civil engineering costs, allowing businesses to go live faster.

Furthermore, being headquartered in China allows NTA to leverage a world-class supply chain and manufacturing ecosystem. This isn't about cutting corners; it's about technical optimization. By refining algorithms to run efficiently on optimized hardware, they deliver the same high-speed throughput as more expensive competitors, ensuring that the vehicle inspection systems pay for themselves through labor savings and reduced claim disputes in a shorter timeframe.

Empowering the Used Car Ecosystem and Auction Groups

While large-scale OEMs like Volvo or GM often deploy high-end scanners at the factory level, the real "pain point" in the industry lies in the remarketing and used car sectors. In an auction environment, speed is everything. If a vehicle can be scanned and its condition report generated in under thirty seconds, the throughput of the entire facility increases.

Elscope Vision has seen significant adoption among Auction Groups and PTI (Periodic Technical Inspection) Centers. In these environments, the system acts as an impartial "digital judge." By removing human bias from the appraisal process, sellers get a fair price, and buyers have total confidence in the vehicle's condition. This standardization is the backbone of the modern "buy-online" automotive trend. Through open API interfaces, Elscope Vision allows these organizations to feed scan data directly into their existing DMS (Dealer Management Systems), creating a seamless workflow from the moment a car enters the lot to the moment it is sold.

Innovation Over Imitation: The R&D Edge

It is a common misconception that "affordable" means "imitation." On the contrary, NTA is a certified high-tech enterprise with numerous software copyrights and patents. Their innovation is particularly evident in their AI's ability to distinguish between harmless dirt and genuine structural damage. By training their models on diverse datasets across more than 30 countries—from the humid environments of Southeast Asia to the harsh winters of Europe—they have built a robust AI that thrives in real-world conditions.

The company's global footprint—spanning Europe, the Americas, and Australia—is a testament to their reliability. They haven't just built a car body damage scanner; they have built a global service infrastructure that supports automated vehicle scanning solutions across diverse vehicle types, from passenger cars to heavy-duty buses and specialty commercial fleets.

Future-Proofing Through Integration and Data Security

As we move toward a more connected automotive future, the data generated by inspection systems for vehicles becomes as valuable as the hardware itself. Elscope Vision’s commitment to an open ecosystem allows for deep integration. Whether it is a logistics hub tracking PDI (Pre-Delivery Inspection) status or a rental agency monitoring a tire sidewall scanners report for safety compliance, the ability to move data securely and efficiently is paramount.

By lowering the barrier to entry, Elscope Vision is not just competing on price; they are accelerating the adoption of safety and transparency standards worldwide. For businesses looking to modernize their operations, the choice is no longer between "expensive AI" and "manual labor." With cost-efficient, high-performance alternatives now available, the era of the fully automated digital inspection has truly arrived.

For more information on intelligent vehicle inspection solutions, visit: https://www.elscopevision.com/.

While pioneers like UVeye have successfully validated the market for automated vehicle scanning solutions, a new challenge has emerged: scalability for the broader market. As global dealerships and logistics hubs seek to digitize without prohibitive capital expenditure, the demand for an Affordable UVeye Alternative for Car Body Damage Scanner has reached a tipping point.

A car body damage scanner is no longer just a luxury for high-end OEMs; it is a critical tool for transparency. These systems utilize high-resolution camera arrays and AI algorithms to identify dents, scratches, and hail damage within seconds as a vehicle drives through a scanning arch. From rental car returns where disputes over "pre-existing damage" are common, to massive automotive auction houses requiring standardized condition reports, these vehicle inspection systems provide a "digital twin" of a car’s exterior, ensuring that no defect goes undocumented.

The Democratization of AI: From Premium Luxury to Industry Standard

The automotive industry is currently navigating a period of intense digital transformation. For years, AI-powered automated vehicle scanning solutions were viewed as a premium "add-on" reserved for the most profitable flagship dealerships or high-volume manufacturers. However, the industry is witnessing a significant shift. The market now understands that AI is not just about the "wow factor"; it is about precision, liability protection, and operational speed.

The primary friction point remains the Return on Investment (ROI). While the value of high-speed scanning is undisputed, many mid-sized dealerships, independent repair shops, and regional fleet operators find the initial investment for tier-one systems difficult to justify. This has paved the way for Elscope Vision, powered by New Tech Automotive Technology (Shanghai) Co., Ltd. (NTA), to bridge the "digital divide." By focusing on cost-efficiency and modular engineering, they provide a path for businesses to adopt elite-level inspection systems for vehicles without the traditional financial barriers.

Elscope Vision: Engineering Full-Stack Solutions for Global Markets

Founded in 2014, NTA has spent a decade perfecting the intersection of hardware and AI. Unlike many companies that simply assemble third-party components, Elscope Vision maintains a full-stack R&D approach. This means the hardware engineering, automation logic, AI algorithms, and cloud architecture are all developed in-house. This vertical integration is the key to their competitive pricing and technical reliability.

Their flagship offerings provide a comprehensive 4-in-1 vehicle inspection system that addresses every critical touchpoint of a vehicle’s exterior:

Arch Scanner (Body & Hail): This car body damage scanner is specifically engineered for high-fidelity detection. While general scanners often struggle with subtle textures, the Dragate system excels in identifying hail damage and PDR (Paintless Dent Repair) requirements. This specialization makes it a preferred choice for insurance adjusters and specialized repair centers.

Undercarriage Scanner (Undercarriage): The undercarriage scanner utilizes 4K high-definition imaging to detect fluid leaks, structural rust, or component wear that is often missed during a quick manual lift inspection.

Tire Tread Depth Scanner & Tire Sidewall Scanner (Tires):Precision is critical to tire safety. The integrated tire tread depth scanner and tire sidewall scanner these two scanners combine line-laser imaging technology with high-resolution visual capture to deliver accurate, repeatable tread depth measurements across all grooves. In parallel, the tire sidewall scanner uses photographic imaging to record key tire information—including tire size, brand, and manufacturing date—while AI algorithms automatically identify sidewall defects such as bulges, cracks, and abnormal deformations. Together, the system provides comprehensive, data-driven tire condition documentation to support consistent and reliable safety assessments.

The Value Proposition: High Performance at a Controlled TCO

When evaluating an affordable Uveye alternative for car body damage scanner, the Total Cost of Ownership (TCO) extends beyond the purchase price. Elscope Vision has optimized the "soft costs" of deployment. Their systems feature modular designs and flexible installation modes—whether surface-mounted, flush-mounted, or mobile configurations. This flexibility significantly reduces site preparation and civil engineering costs, allowing businesses to go live faster.

Furthermore, being headquartered in China allows NTA to leverage a world-class supply chain and manufacturing ecosystem. This isn't about cutting corners; it's about technical optimization. By refining algorithms to run efficiently on optimized hardware, they deliver the same high-speed throughput as more expensive competitors, ensuring that the vehicle inspection systems pay for themselves through labor savings and reduced claim disputes in a shorter timeframe.

Empowering the Used Car Ecosystem and Auction Groups

While large-scale OEMs like Volvo or GM often deploy high-end scanners at the factory level, the real "pain point" in the industry lies in the remarketing and used car sectors. In an auction environment, speed is everything. If a vehicle can be scanned and its condition report generated in under thirty seconds, the throughput of the entire facility increases.

Elscope Vision has seen significant adoption among Auction Groups and PTI (Periodic Technical Inspection) Centers. In these environments, the system acts as an impartial "digital judge." By removing human bias from the appraisal process, sellers get a fair price, and buyers have total confidence in the vehicle's condition. This standardization is the backbone of the modern "buy-online" automotive trend. Through open API interfaces, Elscope Vision allows these organizations to feed scan data directly into their existing DMS (Dealer Management Systems), creating a seamless workflow from the moment a car enters the lot to the moment it is sold.

Innovation Over Imitation: The R&D Edge

It is a common misconception that "affordable" means "imitation." On the contrary, NTA is a certified high-tech enterprise with numerous software copyrights and patents. Their innovation is particularly evident in their AI's ability to distinguish between harmless dirt and genuine structural damage. By training their models on diverse datasets across more than 30 countries—from the humid environments of Southeast Asia to the harsh winters of Europe—they have built a robust AI that thrives in real-world conditions.

The company's global footprint—spanning Europe, the Americas, and Australia—is a testament to their reliability. They haven't just built a car body damage scanner; they have built a global service infrastructure that supports automated vehicle scanning solutions across diverse vehicle types, from passenger cars to heavy-duty buses and specialty commercial fleets.

Future-Proofing Through Integration and Data Security

As we move toward a more connected automotive future, the data generated by inspection systems for vehicles becomes as valuable as the hardware itself. Elscope Vision’s commitment to an open ecosystem allows for deep integration. Whether it is a logistics hub tracking PDI (Pre-Delivery Inspection) status or a rental agency monitoring a tire sidewall scanners report for safety compliance, the ability to move data securely and efficiently is paramount.

By lowering the barrier to entry, Elscope Vision is not just competing on price; they are accelerating the adoption of safety and transparency standards worldwide. For businesses looking to modernize their operations, the choice is no longer between "expensive AI" and "manual labor." With cost-efficient, high-performance alternatives now available, the era of the fully automated digital inspection has truly arrived.

For more information on intelligent vehicle inspection solutions, visit: https://www.elscopevision.com/.

New Tech Automotive Technology(Shanghai) Co., Ltd.

New Tech Automotive Technology(Shanghai) Co., Ltd.

+86 17717670602

mktdept@ntatchina.com

Visit us on social media:

LinkedIn

Facebook

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.